Coating Painting Grade Salt-Resistant CMC Sodium Carboxymethyl Cellulose Paint Thickener

Basic Info

| Model NO. | Instant Fast Dissolve Type CMC |

| Raw Material | Refined Cotton |

| Solubility | Cold or Hot Water Available |

| Application | Detergent, Papermaking, Oil Drilling, Painting, etc |

| Function | Thickening, Stabilization, Water Preserving, etc |

| Viscosity | 2%, 20000-60000cps |

| Transport Package | Composite Kraft Paper Bag, Inner PE Bag |

| Specification | 25kgs/bag |

| Trademark | Sentai |

| Origin | Hunan, China |

| HS Code | 3912310000 |

| Production Capacity | 20000 Tons/ Year |

Product Description

Quick Dissolve CMC / Fast Dissolve CMC / Instant CMC Coating Painting Grade Salt-Resistant CMC Sodium Carboxymethyl CellulosePaint Thickener REPLACE Hydroxyethyl Cellulose HEC

Product Description

Sodium Carboxymethyl Cellulose (also referred as CMC and Carboxy Methyl Cellulose) can briefly be described as an anionic water-soluble polymer produced from naturally occurring cellulose by etherification, substituting the hydroxyl groups with carboxymethyl groups on the cellulose chain.Being readily dissolved in hot or cold water, Sodium Carboxymethyl Cellulose CMC can be produced in different chemical and physical properties.These properties can affect the performance of the product (CMC) in the application, furthermore can be essential for optimizing the production costs.There are a number of parameters which define the properties of the Sodium Carboxymethyl Cellulose CMC.√ Purity (active CMC content): inevitably CMC powder is produced with by products that are sodium salts which comes in the product Sodium Carboxymethyl Cellulose content in the product is the purity.√ Viscosity: one of the most interesting characteristics of the CMC powder is the viscosity which can be from low to high. It is measured mostly by digital viscometers at certain temperatures in different solution rates; such as 1%, 2% or 4%.√ Degree of Substituion: is the average number of sodium carboxymethyl groups per anhydroglucose unit on the cellulose back bone. This parameter in some application areas is quite important to control in the product.√ Physical form: the CMC powder can be produced in fine powder to dust-free granule.

Unique Functions

Thanks to its versatility, CMC can provide different functions and that is what it owes for being used in a range of industries.√Solubility√Rheology√Adsorption on surfacesThese main characteristics help our CMC provide control over properties of the aqueous systems by establishing effects of√ Thickening√ Binding√ Film forming√ Stabilizing√ Protective colloid√ Water retention√ Thixotropy

CMC Paint Grade:

CMC is macromolecule compound with multichain, and the linear chain will open, spread, interact and form the network collide after the water swelling. Meanwhile, the macromolecule chain with oxhydryl has hydration with water and twine with each other, and then increase the water phase viscosity. It has the excellent compatibility in water or in organic solvent, as well as the pigment. It used as thickener, dispersant and stabilizer in coating industry. It usually can replace the Hydroxyethyl Cellulose HEC in Latex paint.1. Application in regular coatingCMC' s oxhydryl macromolecule chain has hydration with water and twine with each other, and then increase the water phase viscosity. It has the excellent compatibility in water or in organic solvent, as well as the pigment. It also can greatly improve the viscosity and rheology, and it used as thickener, dispersant and stabilizer in coating industry. CMC which is applied in water-solube coating will show the effect as follows:*Good water resistance and filming durability;*High fullness of filming, well-distributed of filming, and highlight acquirable,*As the stabilizer, it can prevent the paint-coat from being apart due to the abrupt change of the temperature ;*As the protective colloid, it can maintain the stability of coating system in the wider range of pH value;*As the thickener, it can make the coat well-distributed, and achieve to the expected viscosity for storage and construction, and avoid the serious stratification during the period of storage.*Enhance the coat leveling property, anti splash and anti sagging, so that improve the construction workability;*Make the additives like pigment and filler be dispersed in the coat and the coat will show the excellent effect of pigment adhesion.2. Application in latex paintLatex paint mainly composed of polymer water dispersion and pigment water dispersion. Its viscosity has the influence on settleability, brushability, roll coating, fullness of film, levelling property and the sagging property on the film vertical surface, so it will often adjust the viscosity and rheology of latex paint. While CMC has the advantages of good rheology, small resistance of brush coating, easy for construction, and thus it used as the stabilizer, thickener and water retention agent.*Good thickening effect, high efficiency for latex paint thickening*Be with stability property., and make the paint a certain viscosity with no residue in storage;*Make the moisture permeate the porous substrate slowly, and maintain the water when the latex content is high;*Less limitation on paint formula, small effect by collide type, dispersant and surface active agent;*Coating finishes, and the water action with the CMC will terminate. Regain the viscosity and avoid sagging.3. Application in casting paintCMC is macromolecule compound with multichain, and the linear chain will open, spread, interact and form the network collide after the water swelling. CMC can interact with the sodium base bentonite, and it not only improve the suspending power of sodium base bentonite, but also dramatically reduce the volume of the sediment agglomeration, furthermore, it prevents the fire intolerant aggregate from sinking. Thus, it always used as to enhance the suspensibility rate of the casting paint, and improve the paint viscosity.*Excellent water-solube viscosity increasing, and improve the coating viscosity and rheology;*Good solubility and dispersion, making the solids suspend in the carrier liquid;*Impel the fire intolerant powder suspend and avoid settling, layering and the carrier liquid excessive penetration into the molding material;*Promote the spreading and covering power of paint, and enhance its brushing property and leveling property;*The powder bonds with each other after dried, and adheres firmly on the inside and outside surface4. Special products for coating gradeC2000R has a good ability to resist divalent ions and the glue with C2000R can enhance the stability of white cement and not easy to be mildewed.

Detergent grade CMC:

CMC can be used as THICKENER / thickening agent for liquid detergents, thickening agent for soap.

Detergent grades are mainly used in powder and cream type for detergent production, as well as in soap making industry. With the character of emulsifying and gel protection, CMC will produce the anion during washing and it makes the washed surface and the dirt granule be negatively charged. It prevents re-sticking of the dirt which will be removed by detergent during the cleaning rinsing process. So, the dirt granule has the phase separation property in aqueous phase, and has the repellency with the washed material surface of solid phase. Place dirt then deposit on the washed material, and it can make the white textile keep the whiteness and colored textile bright. CMC can replace hydroxyethyl cellulose (HEC) and Hydroxy propyl methyl cellulose (HPMC) as THICKENER for liquid detergents, which can reduce production cost.

The different types of detergent grades of CMC are produced in the limits of detergent grade specifications but they will be divided into different variations due to customer demands. The customer satisfaction, price sensitivity and other expectations are fully covered by these variations.

CMC PAC Oil Drilling Grade:

CMC and PAC can reduce water loss, and increase viscosity in drilling fluid, cementing fluid and fracturing fluid. They play the roles of protecting the wall of well, taking drilling trifles, protecting drilling bit, preventing mud loss and increasing drilling rate.Usage: add to mud directly or glue solution preparation.Addition: 0.1-0.3% in fresh water mud; 0.5-0.8% in salt water mud.

CMC Food Grade

CMC is widely used in food industry, it play the roles of taste improvement, thickening and stabilization when used in various kinds of dairy drinks and seasonings. As an additive of molding, taste improvement, anti-fragmentation, water retaining and tenacity strengthening, CMC is also used in ice cream, bread, cake, biscuit, instant noodle and fast paste foods.The recommended addition is 0.3-1.0%.

CMC Textile Grade

Is ready to replace traditional sodium alginate with about half of the cost.

CMC Ceramic Grade

Can be used for water preserving in concrete paste and color paste, as adhesive in concrete, sand, and in adhesive layer for wall paper installation.CMC is used for ceramic embryo, glazing pulp and colored glaze in ceramic industry.Addition: 0.03%-0.2% used in ceramic embryo; 0.05-0.2% used in glazing pulp; 1.4-4.0% used in colored glaze.

CMC Toothpaste Grade

CMC has an efficiency of adhesion and molding when used in toothpaste, and stabilizes the quality of toothpaste owing to good compatibleness.The recommended addition is 0.5-1.5%.

CMC Papermaking Grade:

Our CMC can totally replace Finnfix 2, Finnfix 5, Finnfix 10, Finnfix 30, CPKelco CMC, Bondwell QP-10, QX-5, QX-10CMC displays many excellent performance in paper-making technology. it is higher valued by the majority of paper engineers and is widely used in the production of paper and paperboard, such as paper and paperboard coating process, coating rheology modifier, water - retention agent, film-forming agent, auxiliary adhesives, wet end retention enhancers and surface sizing agents, grinding aids, filler modifier and the flocculating agent which used in waste water treatment etc. We have different paper making grades of CMC to meet the different customers' requirements.

Other Industries

As coagulant, water retaining, thickener and binder, Sodium Carboxymethyl Cellulose CMC is also used in paint, carpet gum, mosquito coil incense, tobacco, electric welding, mining, battery, printing and others.

Detailed Photos

1) Fast Dissolve CMC Powder:

Purity%Moisture%T-61%100-300 6.5-8.5≥95.0≤10.0T-81%200-400 6.5-8.5≥95.0≤10.0T-101%300-500 6.5-8.5≥95.0≤10.0ST-11%800-1500 6.5-8.5≥95.0≤10.0C2000R1% 1500-25002%, 300006.5-8.5≥95.0≤10.0C3000R1% 2500-35002%, 400006.5-8.5≥95.0≤10.0C4000R1% 3500-45002%, 500006.5-8.5≥95.0≤10.0C6000R1% 5500-65002%, 600006.5-8.5≥95.0≤10.0

Granular CMC sodium carboxymethyl cellulose products are mainly used in the production of papermaking, ceramics, textile sizing, etc.

| ITEM | D.S | Viscosity(25ºC, Brookfield LVT, mpas) | Purity | pH | Moisture |

| ST-1 | ≥0.9 | 2% 10-20 | 88-95% | 6.5-8.5 | ≤10 |

| ST-2 | ≥0.9 | 2% 20-50 | 88-95% | ||

| ST-3 | ≥0.9 | 2% 50-200 | 88-95% | ||

| ST-4 | ≥0.9 | 2% 300-800 | 88-95% | ||

| ST-5 | ≥0.9 | 2% 800-1200 | 88-95% |

Welcome to look into different grades of Carboxymethyl Cellulose CMC products for various applications above. We can also custom manufacture your desired products with specific requirement of degree of substitution and viscosity.

Packaging & Shipping

Company Profile

Hunan Sentai Biotechnology is located in Xiangtan, Hunan Province, the hometown of great man. Beautiful environment, convenient transportation, company covers an area of 15, 000 square meters, with more than 100 employees and a registered capital of 13.9 million yuan.The company has excellent equipment technology, complete testing equipment and perfect quality system. As one of the major research, production and sales enterprises of CMC, PAC and CMS in China, Sentai's good quality is well known in the market. The current unit capacity is 20000 tons/year.Its products cover papermarking, food, battery, ceramics, oil drilling, detergency, textile printing and dyeing and many other fields. The products sell well all over the country and are exported to United States, Canada, Chile, Peru, Argentina, South Korea, India, Southeast Asia and other countries and regions.The fast dissolving CMC series which independently developed by Sentai are at leading level in China market due to high viscosity and excellent fast speed dissolution."Excellent quality, good service, competitive price" is our principle to support all of our customers. Please feel free to contact us for further information.

Our Advantages

As our chief engineer has worked for, our technology originates from the world-renowned companies, and we are one of the member of China Cellulose Industry Association since 2012 which assure the stable and high quality CMC for customers.

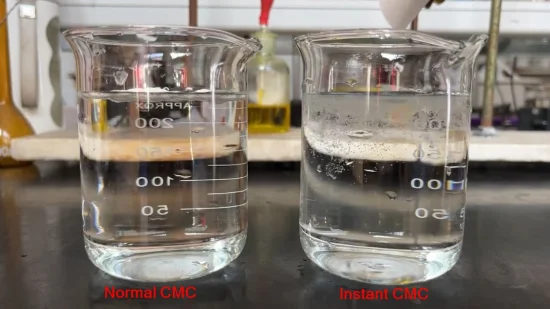

Let's see the picture on the left side. There are two cups of instant CMC solution which dissolved in the same conditions.The left cup was produced by another company. The solution was turbid.The right one was made by Sentai, which is as clear as pure water.Not only the appearance is better, our viscosity is also more stable after stored for a long time. Other company's CMC viscosity is easily to drop. Welcome to have our CMC sample tested.

Please leave us messages via Made-In-China describing your usage plan. Free sample is available. Please contact us for more information or quotation.