Tire Crushing Machine Tire Granulator Crumb Rubber Equipment

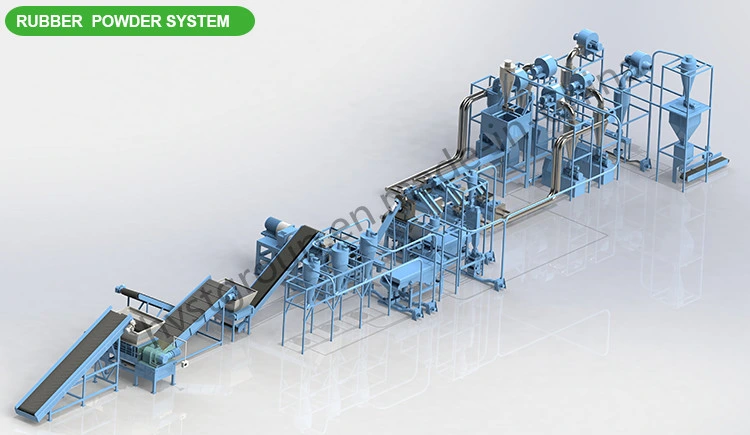

tire crushing machine tire granulator crumb rubber equipment Introduction of Fully automatic waste tire recycling system

Basic Info

| Motor | Famous Brand Siemens |

| Waste Tire Production Line | OTR, Big Truck Tire, Car Tire, etc |

| Control | PLC and Computerized |

| Lead Time | 1-3months Based on The Capacity |

| Color | Customerized |

| Service | Installation and Training |

| Spare Parts | We Offer All Spare Parts |

| Using Time | More Than 10 Years |

| Rubber Mulch Production Line | Process Tire to 10-30mm Wire Free Rubber Mulch |

| Technology Service | Custom Design Technical Proposal |

| Quality Assured | 100% Tested |

| Blades,Shaft etc Parts | High Quality Material, Precise Processing Way |

| Quality | Advanced Technology Waste Tire Recycling System |

| Price | Competitive Factory Price |

| Transport Package | as Designed |

| Specification | as designed |

| Trademark | HVST |

| Origin | Henan, China |

| HS Code | 8477800000 |

| Production Capacity | 100set/Year |

Product Description

tire crushing machine tire granulator crumb rubber equipmentIntroduction of Fully automatic waste tire recycling system

1.The tire recycling machine product consists of four main machine parts: shredders, rasper, granulators, and miller. The rubber size will be shred smaller and smaller, such as 50-70mm, 10-30mm, 1-5mm, 30-120mesh.

2. The steel will be separated in second step rasper machine, the nylon fiber will be separated in third step granulator

3. The whole production line use advanced technology, use siemens PLC control sysem, automatic level is high.

4. can process various waste tire, such as car tire, truck tire, even OTR tire up to 4m

Flowchat of the Intelligent fully-automatic tire recycling plant:

From first step tire shredder, the waste tire was processed into rubber blocks;

From second step rasper machine, you can get smaller rubber chips 10-30mm as request, and the wire steel was separated, the output rubber mulch is clean without steel.

From third step granulator, you can get smaller rubber granule 1-6mm, and the nylon was separated;

The last step miller, you can get fine rubber powder.

Detailed image:1. Double tire shredder: It to designed to shred whole waste tire into rubber chips, 50-150mm as request

| Model | Input size | Output size | Capacity | Motor | Blades quantity | Dimensions | Weight |

| TS-800 | 50*50mm | 1-2T/h | 2*22kw | 16pcs | 4x2.6x3.2m | 8T | |

| TS-1200 | 1200mm | 60*60mm | 3-5T/h | 2*37kw | 20pcs | 4 .8x2. 8 x 3 . 5 m | 14T |

| TS-1600 | 1600mm | 50-150mm | 6-8T/h | 2*45kw | 16-30pcs | 5x2x3.4m | 18T |

| TS-1800 | 1800mm | 50-150mm | 7-10T/h | 2*55Kw | 20-24pcs | 5.6x2x3.4m | 23T |

| TS-2000 | 2000mm | 75-200mm | 10-15T/h | 2*75kw | 20-30pcs | 6x2.4x4m | 36T |

| TS-2400 | 2400mm | 100-200mm | 20-30T/h | 2*110kw | 16-24pcs | 7.4x3.2x5.2m | 56T |

2.Rasper

It is specially designed to remove wire steel from tire, and process the rubber chips from tire shredder into 10-30mm wire-free rubber mulch.

| Model | R-315 | R-132 | R-90 | R75 | R55 | R45 |

| Capacity | 3-6t/h | 1.5-3t/h | 1-1.5t/h | 700kg-1t/h | 500-700kg/h | 300-500kg/h |

| Poder | 315kw | 132kw | 90kw | 75kw | 55kw | 45kw |

| Weight | 2400kg | 6100kg | 4200kg | 3500kg | 1850kg | 1700kg |

| Voltage | As request | |||||

| Size | 10-30mm | |||||

It is designed to process the rubber mulch into 1-6mm rubber granule, and separate the nylon fiber.

| Model | G-90 | G-45 | G-37 |

| Power | 90kw | 45kw | 37kw |

| Capacity | 800-1500kg/h | 500-800kg/h | 300-500kg/h |

| Final size | 1-6mm | 1-6mm | 1-6mm |

| Weight | 5600mm | 3300mm | 2950mm |

It is designed to process the rubber granule into fine rubber powder 30-120mesh as request

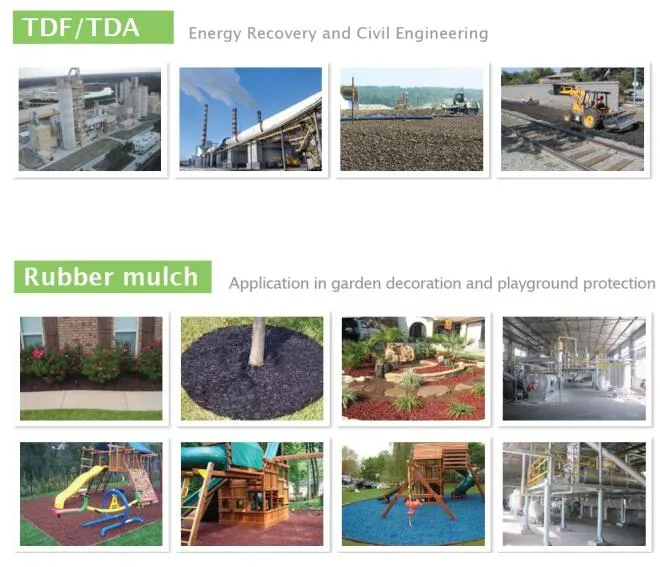

Application for example:

Company:

We has been focused on designing and manufacturing equipment for the recycling industry more than 20 years and is emerging as a leader in providing cost effective turnkey tire recycling systems. Our main focus is to provide custom designed tire recycling systems that deliver optimum production for a variety of applications such as TDF (Tire Derived Fuel), rubber mulch, and rubber granule(crumb), rubber powder. We have manufactured and installed recycling systems in countries all over the world.

Service:

Before-sales service:

1. Technical proposal

2. Answer questions within 8 hours

3. Tested machine

After-sales service:

1. Install and debug machine, train workers

2. Free spare parts within gurantee period

3. Long time technical support when production process

FAQ:

1) Are you a factory or trade company?

We are professional recycling line machine factory, professional design engineer, experienced production team, advanced manufacturing and processing facility. You can get good technical support from us.

2) How can I trust your company?

a. famous brand component as our standard configuration, like Siemens Motor,Siemens PLC and Schneider component. All parts use high quality material and precise processing

b. Assessed by third party-national test centre. national patents,SGS, CE, ISO certificate

c. Welcome to visit our factory to check at any time, We're at Zhengzhou, Henna, China

3) How about the test running & installation?

Before shipping out your machines, we will invite you to come to test your machines, when you are satisfied; we start to pack and delivery.

We will dispatch our enginne to your country to help you to install and debug the machine, as well as training your workers.

4) How about the warranty?

Under the proper usage, 1-3 year for whole machine, we provide long-time after sales service for our customer.

Send to us