Zambia Lead Zinc Separation Equipment Mineral Flotation Cell

Products Description Introduction of Gold Lead Zinc Separation Equipment Flotation Machine Flotation machine, in the ore

Basic Info

| Model NO. | SF-8 |

| Energy Saving | Energy Saving |

| Warranty | 1 Year |

| Color | Blue |

| Customized | Customized |

| Condition | New |

| Transport Package | Full Container Loading |

| Specification | 1124 |

| Trademark | JXSC |

| Origin | China |

| HS Code | 84741000 |

| Production Capacity | 100 Per Month |

Product Description

Products Description

Introduction of Gold Lead Zinc Separation Equipment Flotation Machine

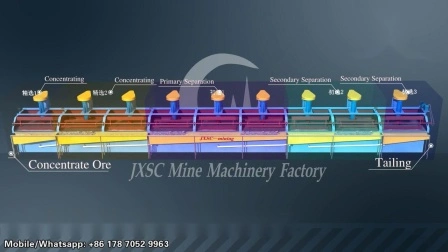

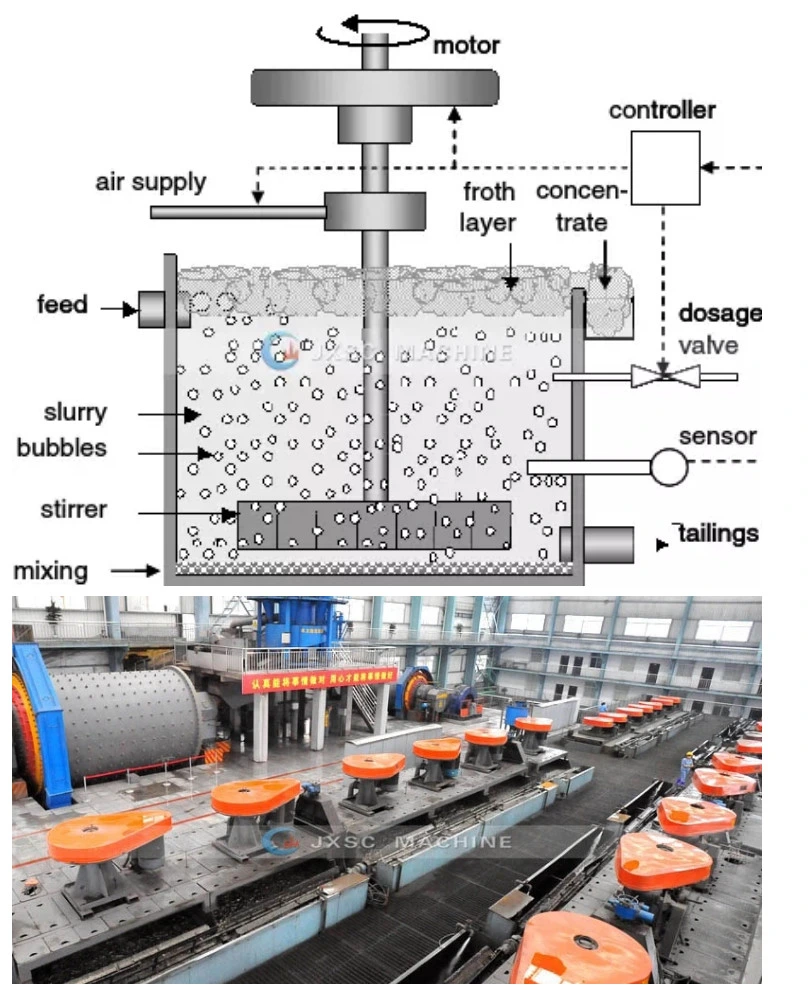

Flotation machine, in the ore dressing, mainly used for separating copper, zinc, lead, nickel, gold and other Non-ferrous metal, can also be used for Ferrous, non-metallic crude and selected.After mixing the crushed ore with water and flotation reagent, the ore is mixed into a slurry tank, which is filled with air to form a large number of air bubbles. Some mineral particles which are not easily wet by water attach to the air bubbles and float to the surface of the pulp together with the air bubbles The formation of mineralized bubble layer, some easy to be water wet, hydrophilic mineral particles not attached to the bubble, and stay in the pulp, will contain specific minerals mineralized bubble discharge, so as to achieve the goal of mineral processing.

Features of Lead Zinc Separation Equipment Flotation Machine

1. High flotation efficiency and low energy consumption.2. Long Service Life of wearing parts.

3. The flotation machine is equipped with high self-configuration, and has the functions of suction, Pulp Suction, and flotation, and does not need any auxiliary equipment.

4. Mechanical Mixing, easy to operate and adjust.

5. It can combine with other mineral equipment, sand making machine, sand washing machine to separate ore, the effect is better.

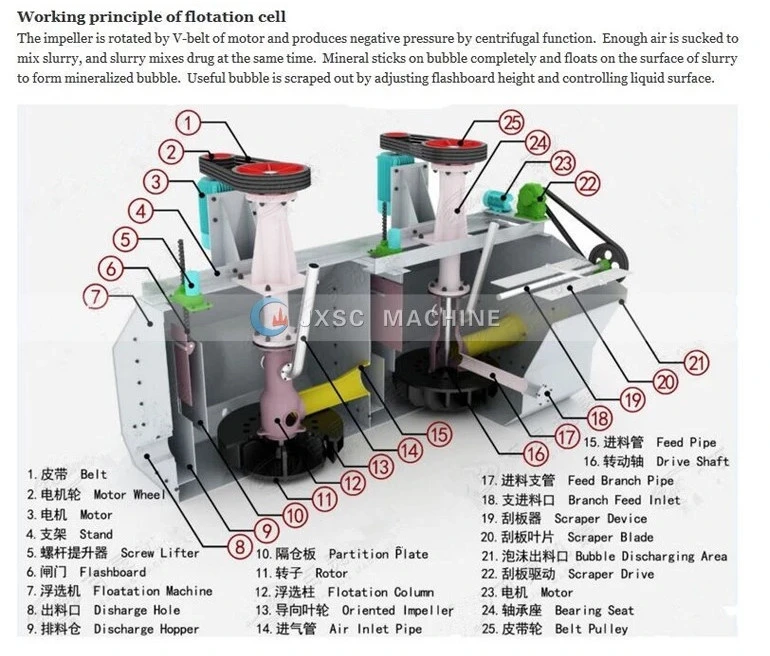

Product Structure of Lead Zinc Separation Equipment Flotation Machine

The metallurgist flotation mainly made up of slurry-supporting Trough, mixing device, aeration device, mineralized bubble discharging device and motor. Flotation cell is mainly used to select nonferrous metals such as copper, zinc, lead, nickel, gold, etc., and also be used for coarse selection and selection of black metal and nonmetal.

With the poor, fine, hybridized primary mineral resources and the increasing complexity of mineral processing technology, energy consumption and production costs, it is necessary to strengthen the research of flotation equipment in the following aspects. JXSC, focus on the mineral equipment business since 1985, CE, SGS certified.

Technical Parameters of Lead Zinc Separation Equipment Flotation Machine

we can choose the model according processing capacity and mineral particle size. The best feeding size is 200 mesh account for 80% or more.

| Model | Volume | Cell size | Impeller Dia. | Impeller speed | Capacity | Power | Singe cell weight |

| Unit | m3 | mm | mm | r/min | m3/min | kw | kg |

| XJK-3A | 0.35 | 700×700×700 | 300 | 483 | 0.18-0.4 | 2.2/0.55 | 430 |

| XJK-4A | 0.62 | 820×900×850 | 350 | 400 | 0.3-0.9 | 3/1.1 | 755 |

| XJK-5A | 1.1 | 1100×1100×1000 | 500 | 330 | 0.6-1.6 | 5.5/1.1 | 1416 |

| XJK-6A | 2.8 | 1750×1600×1100 | 600 | 280 | 1.5-3.5 | 11/1.1 | 2113 |

| XJK-7A | 5.8 | 2200×2200×1200 | 750 | 240 | 3-7 | 22/1.5 | 3400 |

| SF-0.37 | 0.37 | 700×700×750 | 296 | 386 | 0.2-0.4 | 1.5/0.55 | 468 |

| SF-0.7 | 0.7 | 820×900×950 | 350 | 400 | 0.3-0.9 | 3/1.1 | 805 |

| SF-1.2 | 1.2 | 1100×1100×1100 | 450 | 312 | 0.6-1.2 | 5.5/1.1 | 1373 |

| SF-2.8 | 2.8 | 1700×1600×1150 | 550 | 268 | 1.5-3.5 | 11/1.5 | 2138 |

| SF-4 | 4 | 1850×2050×1200 | 650 | 220 | 2-4 | 15/1.5 | 2582 |

| SF-8 | 8 | 2200×2900×1400 | 760 | 191 | 4-8 | 30/1.5 | 4129 |

| SF-10 | 10 | 2200×2900×1700 | 760 | 191 | 5-10 | 30/1.5 | 4486 |

| SF-16 | 16 | 2850×3800×1700 | 760 | 191 | 5-16 | 30×2/1.5 | 8320 |

| SF-20 | 20 | 2850×3800×2000 | 760 | 191 | 5-20 | 30×2/1.5 | 9828 |

Successful Project

JXSC has proveded many mineral plant cases. Except for manufacturing of the mining equipment, JXSC also can provide engineering consultation, mineral processing experiments, mine design, installation and commissioning, personal training, track service, management of dressing plant, etc one package service. Make customer worriless whole-process, shorten construction period and get profit earlier.

FAQ

1.How is the quality of your products?(mining equipment/machine)

Answer: Our products are manufactured strictly according to national and international standard, and we will take a test on every grinder before delivery.

2.Guaranteed:

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.

Contact US

If you are interested with our products, please don't hesitate to contact us. You can tell me the following questions, so that we can send you accurate quotation soon, including extra discounts!

1. Which machine do you need? like gold washing machine, spiral chute, vibrating screen, Jig separator, Shaking table, stone crusher, jaw crusher, impact crusher etc.

2. What is your raw material plan to process? like gold ore, diamond ore, tantalite ore or inron ore, etc.

3. The capacity you need? Like 100 tones per hour or 2000 tones per day.

4. Your contact information? Both Email and phone number are essential, we can contact you easier.

Send to us